Cocobolo Wood: Uses and characteristics

Introduction

Cocobolo wood, botanically known as Dalbergia retusa, is a tropical wood considered one of the most valuable species of the genus Dalbergia for its exceptional mechanical and aesthetic properties and density.

Native to Central America (Nicaragua, Costa Rica, Panama and Belize), it is subject to strict regulations for its exploitation and slow growth. The purpose of this post is to offer a complete technical analysis on its characteristics, uses and recommendations for responsible use.

Origin and sustainability

- Geographical distribution: It grows mainly in coastal areas and dry forests of Central America.

- Maturity and exploitation: It requires between 80 and 100 years to reach maturity and its felling has produced a drastic reduction in original populations.

- Regulation: It is included in Appendix II of CITES and assessed as vulnerable (IUCN), which limits its trade even in the form of finished products weighing more than 10 kg. The cocobolo wood available for purchase comes from historical felling, so its availability is extremely low and usually in small format: for pens, knife handles, etc.

- Reforestation: There are already FSC-certified projects to promote its legal and sustainable cultivation, so it is expected to be available again in the future.

Physical and mechanical properties

| Property | Typical Value / Description |

|---|---|

| Density | 990–1250 kg/m³ (≈ 0.99–1.25 g/cm³) |

| Janka hardness | ≈ 2,960 lbf (≈ 14,140 N) one of the highest |

| Shrinkage/drying | Low to moderate; requires slow drying due to density |

| Durability | Highly resistant to water, insects and moisture changes |

| Texture/grain | Very fine, straight to interleaved grain; Natural Shine |

Technical notes:

- Its density makes buoyancy unlikely: it sinks in water.

- Working with fine serrated tools can get bogged down by their natural oils.

Appearance and colour behaviour

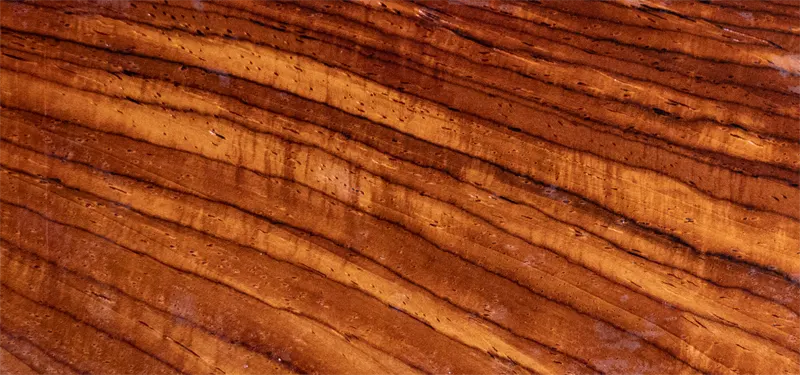

- Heartwood color: combines shades from orange, red, yellow to dark brown, with black, purple or even greenish veins.

- Slabwood: creamy yellow or almost white, with a marked boundary with respect to the heartwood.

- Change over time: when in contact with air, it darkens and gains chromatic depth; It can exude oil and darken nearby areas if they are not properly sealed.

Workability and finishing

- Machining: carbide or Stellite tools are recommended for milling and planing; risk of pulling out with interleaved grain.

- Gluing: difficult because of the oils; Pre-cleaning with acetone or thinner, and slow-curing adhesives such as epoxy is recommended.

- Polishing and polishing: easy to achieve a crystalline finish with fine sanding and natural waxes; Highly appreciated shine.

- Health and safety: dust and contact can cause severe allergic reactions (eye, respiratory, skin irritation, even athmatic symptoms). Use of mask, ventilation and gloves is mandatory.

Main uses

Due to their combination of beauty, hardness and water resistance, these are the most prominent present and/or past uses:

- Musical instruments: bodies, fingerboards, and necks of guitars and basses; mouthpieces and barrels for clarinets and oboes; Bagpipe or drone pipe constructions instead of Granadillo.

- High-end billiard cues and decorative inlays such as inlay.

- Handles of frequently used knives, guns and tools: for mechanical resistance and visual presence.

- Turned handicrafts: bowls, pens, jewelry boxes, pipes, decorative sculptures.

- Luxury furniture and decorative veneers: emblematic desks, tables, high-status furniture.

Advantages and limitations

Advantages

- Unique aesthetics with dramatic veins and depth of color.

- High hardness and durability against moisture, insects and wear.

- Excellent polishing and polishing ability.

- Clear sonority in acoustic or percussive applications.

Limitations

- Impossible to achieve in large formats due to its regulation and serious state of conservation.

- Difficult to work with: challenges tools, hits badly and wears blades.

- Health risks when working without adequate protection.

- Instability in color: It can stain adjoining areas if not sealed carefully.

Conclusion

Cocobolo wood is a material with outstanding technical and aesthetic characteristics, ideal for exclusive objects such as knives, pens or high-quality musical instruments, but its very low current availability due to its very serious state of conservation makes it practically a historical curiosity until plantation wood is available.

Frequently Asked Questions

What is cocobolo wood and where does it come from?

Cocobolo wood is the heartwood of trees of the genus Dalbergia, primarily Dalbergia retusa, native to Central America, in countries such as Nicaragua, Costa Rica or Panama. Its exploitation is regulated by CITES and is listed as vulnerable by the IUCN.

What is the density and hardness of cocobolo wood?

It is extremely dense, with a density of up to 1.1 g/cm³, and a Janka hardness of about 2,960 lbf (≈ 14,140 N), making it one of the hardest in the plant world.

How does its color change over time?

The heart of the wood darkens after cutting, intensifying its red, orange and brown hues, and the black or purple grains stand out. It can even stain nearby surfaces if it is not sealed properly.

What is it mainly used for?

It is used in musical instruments, luxury furniture, pool cues, knife handles, turned crafts, heavy-duty flooring or exclusive decorative details.

What precautions in your machining?

Prior cleaning with solvents, use of carbide tools, suitable adhesives and always respiratory, visual and dermal protection against its allergenic potential is recommended.

Is cocobolo wood sustainable?

The state of conservation of cocobolo is serious, so its felling is prohibited. The availability of this wood is very low, since the one we can find for sale comes from trees cut down decades ago and in most cases the format available for its acquisition is very small: to make pens, knife handles or pieces of musical instruments

Why is it not easy to stick cocobolo?

Due to its natural oil and silica surface content, pre-decontamination and the use of slow-curing epoxy are recommended to ensure optimal bonding.

Does cocobolo wood have a specific smell?

Yes, it gives off a floral-spicy aroma when working with it, which can be strong for some people, it has even been used in perfumes.

What care does it require after using it on a final object?

Regular cleaning with a dry or slightly damp cloth, periodic application of natural oils and avoid prolonged exposure to UV rays or aggressive liquids.

Otras entradas del blog

Cedar Wood: Uses and Characteristics

Hard Maple Wood: Uses and Characteristics

Walnut Wood: Uses and Characteristics

Oak Wood: Uses and Characteristics

Nuestras tablas de cortar:

Linea

Oak oak cutting board

Linea

Oakoak cutting board

Calida

end grain cutting board

Linea

Maple grain maple board

Linea

Maplegrain maple board

Linea

Walnut Walnut cutting board

Linea

WalnutWalnut cutting board